In the short time I’ve owned a 3D printer I have called it many things. A 3D printer is “the best reason to own a 3D printer” or “the most fun optimization problem I’ve ever faced.” It may have also been called some other things but I don’t like to gossip. In the spirit of perpetual optimization, I was tempted to improve my print surface and willing to try anything.

All those fancy Ultimakers and Rostocks printing on glass. It was obviously a superior bed surface to my bubbly Kapton and it wouldn’t need to be replaced (at least for a long time). Plus the internet said it was easy (if this adorable kid can do it, so can I!).

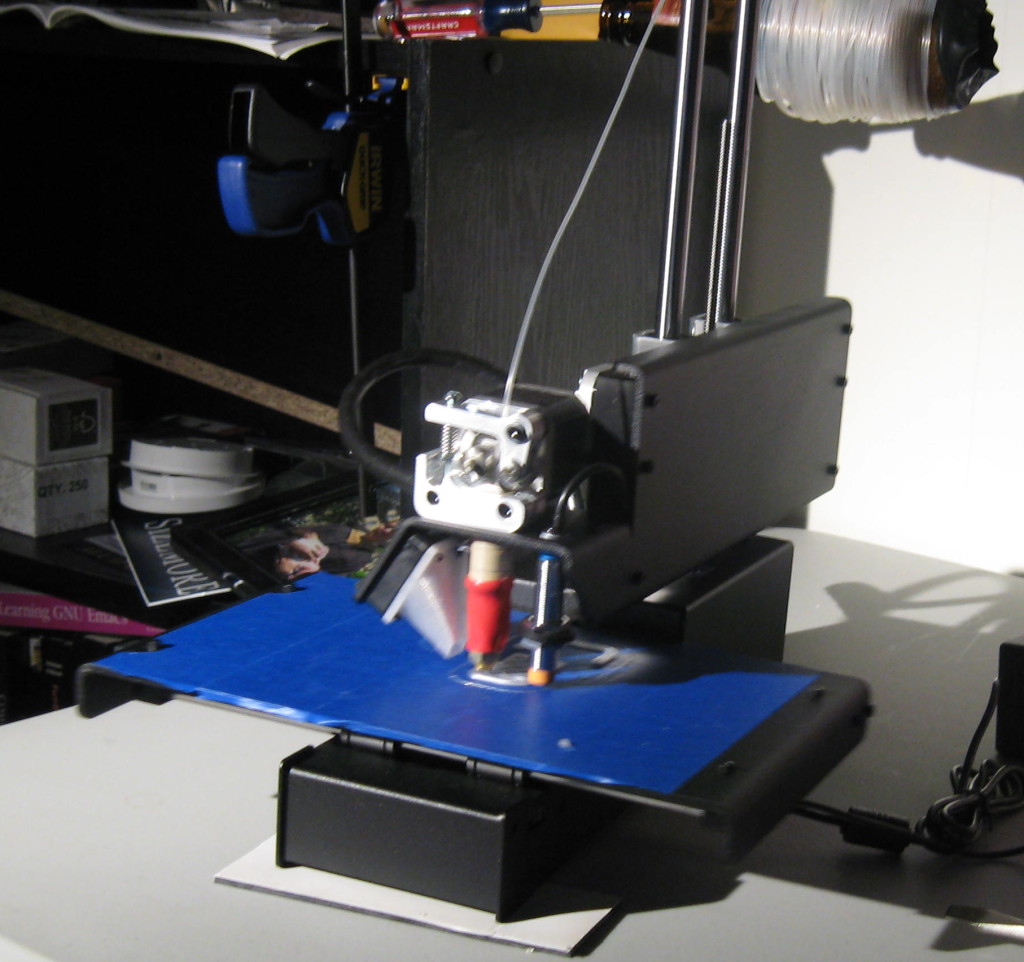

First let’s take a look at past print surfaces:

Both tape (blue masking and Kapton) worked fine. But it was difficult to remove parts and the tape got scuffed up and in some case tore off. Glass was definitely a more elegant solution.

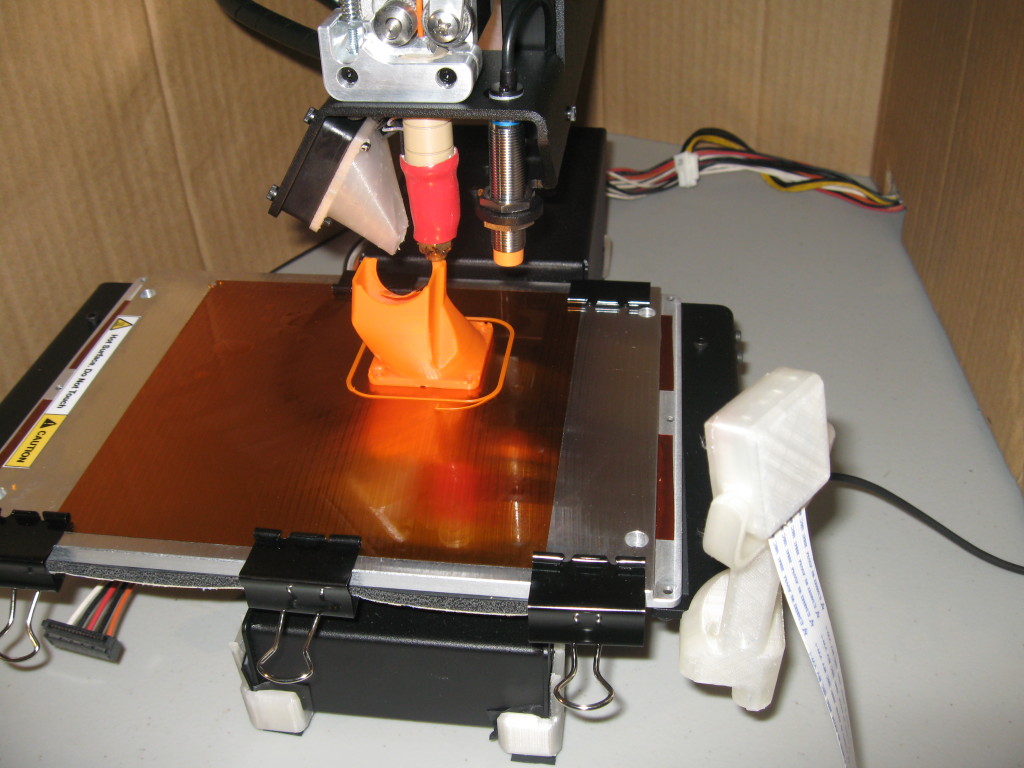

I picked up 3 mm thick glass from a picture frame and needed to make one cut to get it down to size. After several failed cuts I finally got something that was functional and minimally dangerous. As I went to apply the glass to the bed I quickly found another problem. The auto-leveling inductive probe would only sense the aluminum bed at about 2.5 mm away. The probe was more sensitive to ferrous metals so I took a magnet and went looking for large flat pieces of metal around the lab. What I found was the back of a breadboard. After removing the binding posts and cleaning it up a bit added it to my growing sandwich of a print bed. The final piece was some silicone baking sheets (like these) in between the metal and glass to prevent any slippage. The final product is shown below.

Once this was all clipped into place it actually worked pretty well. I should mention, don’t overconstrain the glass. I was using four binder clips which produced significant warpage in the glass. Once I removed one of the clips my glass plate magically leveled out again. Mathematical.

It takes a long time to warm up, but it does work. And you wouldn’t believe how well it holds heat…

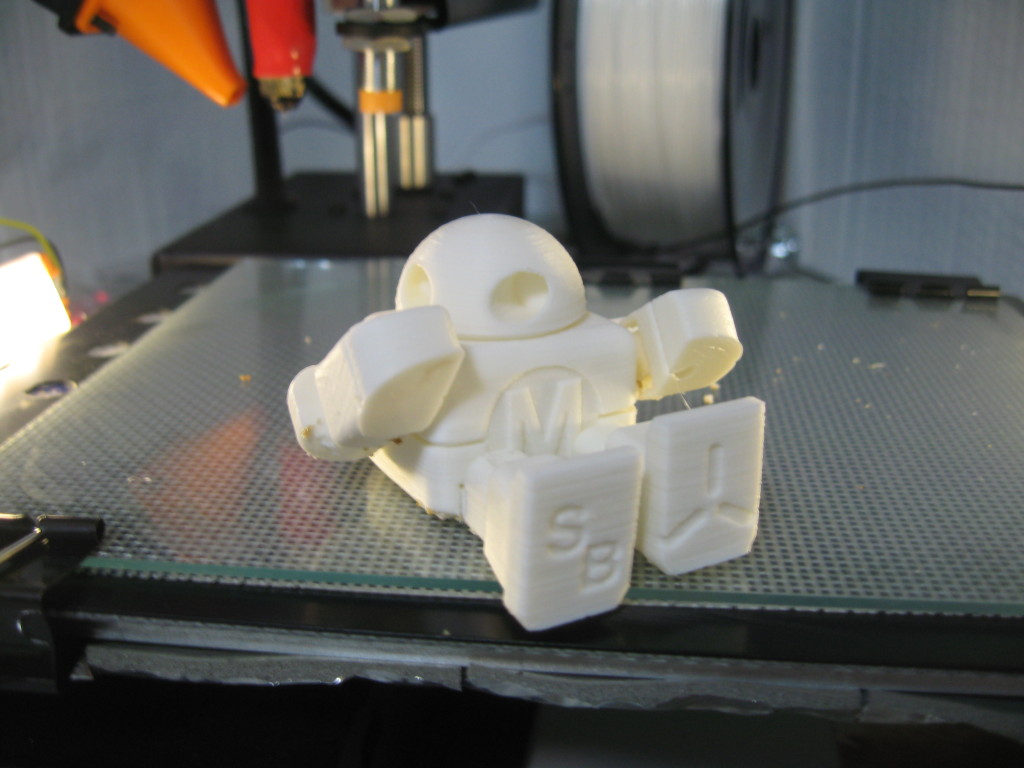

See it in action, from multiple angles!